Picture a factory floor where robotic arms dance in perfect sync, assembling car parts with precision that rivals a surgeon’s hand, all while workers oversee operations from sleek control panels. This is the reality of abb robotics, a powerhouse in automation that’s reshaping how America builds, innovates, and competes globally. From Detroit’s auto plants to Silicon Valley’s tech labs, ABB’s robots are boosting productivity, enhancing safety, and creating new opportunities in a fast-evolving world. Whether you’re a manufacturer aiming to streamline operations, a worker curious about tech-driven careers, or a techie fascinated by intelligent machines, let’s dive into how abb robotics is transforming American industry, with insights from Reddit’s vibrant communities and expert voices to light the way.

Understanding ABB Robotics

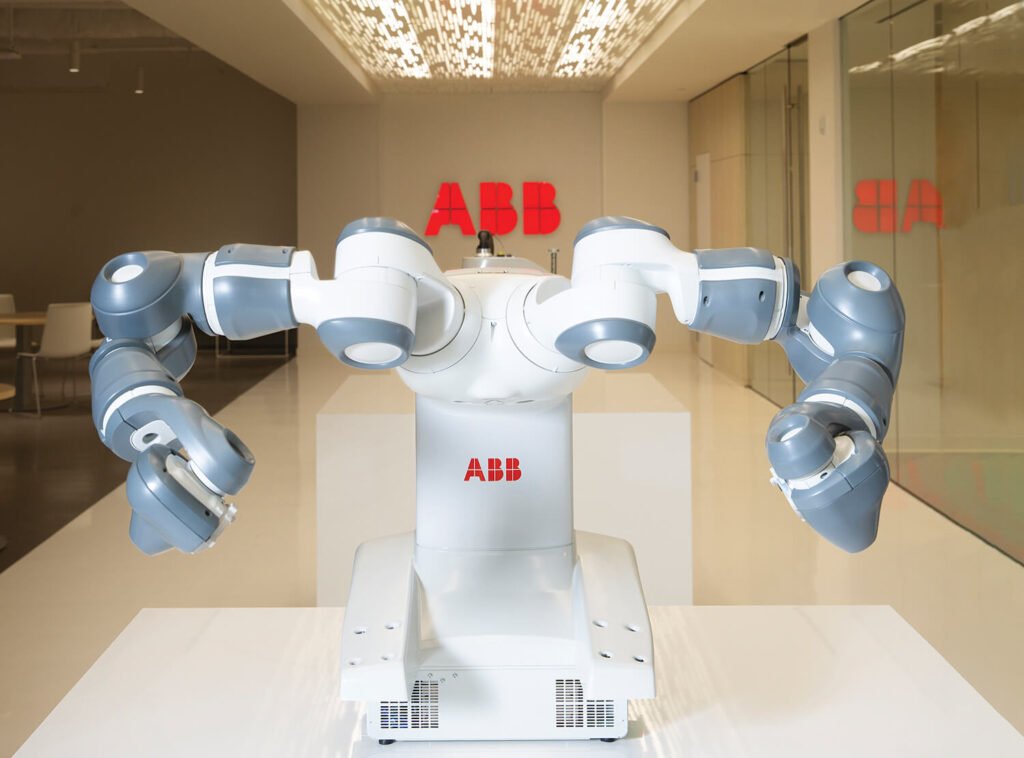

ABB Robotics, a division of the Swiss-Swedish multinational ABB, designs and manufactures industrial robots, collaborative robots (cobots), and automation software that power modern factories. Since its founding in 1988, ABB has grown into a global leader, with a strong footprint in the U.S., where its robots tackle tasks like welding, assembly, material handling, and painting. Known for models like the IRB 4600 and YuMi cobot, abb robotics blends cutting-edge AI, machine learning, and vision systems to deliver unmatched precision and flexibility.

On Reddit’s r/robotics, a user shared, “ABB’s IRB 4600 is a beast—programmed it for pick-and-place, and it’s scary accurate.” This reflects the real-world impact of ABB’s technology in American plants, where reliability and ease of programming make it a go-to choice. Consequently, ABB’s robots are not just tools but partners in redefining manufacturing efficiency.

Why It Matters to America

The U.S. manufacturing sector, from automotive to electronics, faces pressure to innovate amid global competition and labor shortages. Abb robotics addresses these challenges by automating repetitive or dangerous tasks, allowing workers to focus on creative and strategic roles. With factories in states like Michigan and Alabama, ABB supports American industries while creating tech jobs in robot programming, maintenance, and system integration. Moreover, its push for sustainability—like energy-efficient robots—aligns with America’s green initiatives.

A r/PLC user noted, “ABB’s RobotStudio is a game-changer for simulating setups before going live—saves tons of downtime.” This highlights how ABB’s software tools, like RobotStudio, empower American engineers to optimize production without costly trial-and-error, keeping the U.S. competitive.

ABB Robotics: Core Applications in the U.S.

America’s auto industry, a cornerstone of its economy, relies heavily on abb robotics. Robots like the IRB 6700 handle spot welding, assembly, and paint application in plants for Ford, GM, and Tesla. These machines work tirelessly, ensuring precision and consistency while reducing worker exposure to hazardous tasks like heavy lifting or toxic fumes. By automating production lines, ABB helps carmakers meet demand for electric vehicles and smart cars without compromising quality.

Reddit’s r/manufacturing praises ABB’s role, with one user saying, “Our ABB welders cut defects by half—worth every penny.” Thus, for American automakers, ABB’s robotic arms are a lifeline, balancing speed, cost, and reliability in a cutthroat market.

Electronics and Consumer Goods

Beyond cars, abb robotics shines in electronics, where collaborative robots like YuMi assemble delicate components for smartphones, laptops, and appliances. These cobots work alongside humans, handling tasks requiring dexterity and accuracy, such as circuit board assembly or packaging. In warehouses, ABB’s autonomous mobile robots (AMRs) streamline logistics, moving goods for giants like Amazon with AI-driven navigation.

A r/technology thread mentioned, “ABB’s cobots are creepy good at tiny tasks—saw one thread a needle in a demo.” This precision makes ABB indispensable for American companies racing to produce high-tech gadgets and consumer products efficiently.

Food and Beverage Industry

The food sector is another frontier for abb robotics, where robots ensure hygiene and speed in processing, packaging, and palletizing. From sorting fruit to packing snacks, ABB’s food-grade robots meet strict FDA standards, reducing contamination risks. In breweries or bakeries, they handle repetitive tasks, freeing workers for quality control or recipe innovation.

Reddit’s r/automation shared, “ABB robots in our plant pack 10,000 boxes a day—humans couldn’t keep up.” For American food producers, this means scalability and consistency, critical in a market driven by fast delivery and freshness.

Skills and Careers in ABB Robotics

As abb robotics expands, so does demand for skilled Americans in robot programming and maintenance. Tools like RobotStudio let engineers design and simulate robotic systems, requiring knowledge of RAPID, ABB’s programming language. Maintenance techs troubleshoot kinematics, sensors, and controllers, ensuring uptime. These roles blend coding, mechanical skills, and problem-solving, offering high-paying jobs in cities like Auburn Hills or Houston.

A r/PLC user advised, “Download RobotStudio’s free trial and mess around—it’s how I prepped for my ABB gig.” This hands-on approach is key for Americans entering the field, where certifications like ABB’s IRC5 Programming boost employability.

Emerging Roles in AI and Integration

The rise of AI and machine vision in ABB robots opens doors to roles in system integration and data analysis. Integrators customize robots for unique tasks, like 3D printing or laser cutting, while data specialists optimize performance using IoT analytics. These jobs require STEM skills and creativity, appealing to America’s tech-savvy workforce.

Automation expert Dr. Laura Simmons says, “ABB Robotics is shifting jobs from manual labor to brainpower—workers now design, not just do.” Her insight, echoed in r/careerguidance, underscores how ABB creates future-proof careers for Americans in a digital economy.

Challenges and Realities

While abb robotics offers incredible benefits, its complexity can intimidate newcomers. Programming robots like the IRB 4600 demands familiarity with kinematics and software interfaces, and ABB’s training courses, though comprehensive, aren’t cheap. A r/robotics user lamented, “ABB’s RobotStudio II class was intense—great but pricey for a solo learner.” For American startups or small businesses, initial costs for robots and licensing can also be steep, though ROI often justifies the investment.

To ease this, ABB provides free trials and online tutorials, helping beginners build skills. For companies, leasing options and government grants for automation can offset expenses, making abb robotics accessible.

Workforce Transition

Automation sparks debate about job displacement, and abb robotics is no exception. While robots handle repetitive tasks, they shift workers toward technical roles, requiring reskilling. In Rust Belt states, where manufacturing is king, this transition can feel daunting. A r/AskEngineers user noted, “Some guys fear robots taking their jobs, but ABB’s cobots need humans to thrive.”

By investing in training programs, ABB helps American workers adapt, offering apprenticeships and community college partnerships. This ensures automation empowers, not replaces, the workforce, aligning with America’s push for inclusive growth.

The Future of ABB Robotics in America

ABB’s commitment to R&D keeps it ahead, with $280 million invested in a new Swedish factory and plans for U.S. expansion. Emerging tech like 5G-enabled robots, digital twins, and augmented reality for maintenance promises to revolutionize American factories. For instance, OmniCore controllers integrate IoT for real-time analytics, optimizing supply chains.

Reddit’s r/Futurology buzzed, “ABB’s new cobots might run ROS soon—imagine factories talking to each other.” This vision of connected automation positions America to lead in Industry 4.0, blending robotics with smart manufacturing.

Sustainability and Ethics

As America tackles climate change, abb robotics supports green manufacturing. Its energy-efficient robots cut power use, and recyclable designs reduce waste. Ethically, ABB emphasizes human-robot collaboration, ensuring technology serves people, not vice versa. A r/environment user praised, “ABB’s AMRs in warehouses save fuel—no more gas-guzzling forklifts.”

By prioritizing sustainability, ABB aligns with American values, appealing to eco-conscious businesses and workers who want purpose-driven careers.

Concluding Thoughts

Abb robotics is more than a tech trend—it’s a catalyst for America’s industrial renaissance, blending precision, innovation, and opportunity. From welding cars to packing snacks, its robots make factories smarter, safer, and greener, while opening doors to high-tech careers for workers nationwide. With Reddit’s real-world stories and expert insights, it’s clear ABB isn’t just automating tasks—it’s reimagining how America works, builds, and dreams.

So, whether you’re a manufacturer eyeing efficiency, a coder craving impact, or a dreamer inspired by futuristic tech, dive into the world of abb robotics. Explore RobotStudio, connect with online communities, or tour a local plant. The future’s here, and with ABB, America’s ready to shape it—one robot at a time. Here’s to a stronger, smarter 2025!

Small Business Ideas UK: Million-Dollar Concepts Americans Must Steal Now!